- Medical automation equipment

- Automatic equipment for blood glucose test paper production

- Colloidal gold test paper production automation equipment

- Automatic filling equipment for biological reagent production

- Micro quantitative spray point equipment and automation platform

- Medical devices & consumables production and assembly equipment

- Automatic equipment for drug sorting and packaging

- Educational training equipment

- CCD visual inspection equipment

- Intelligent production line equipment

Product Details

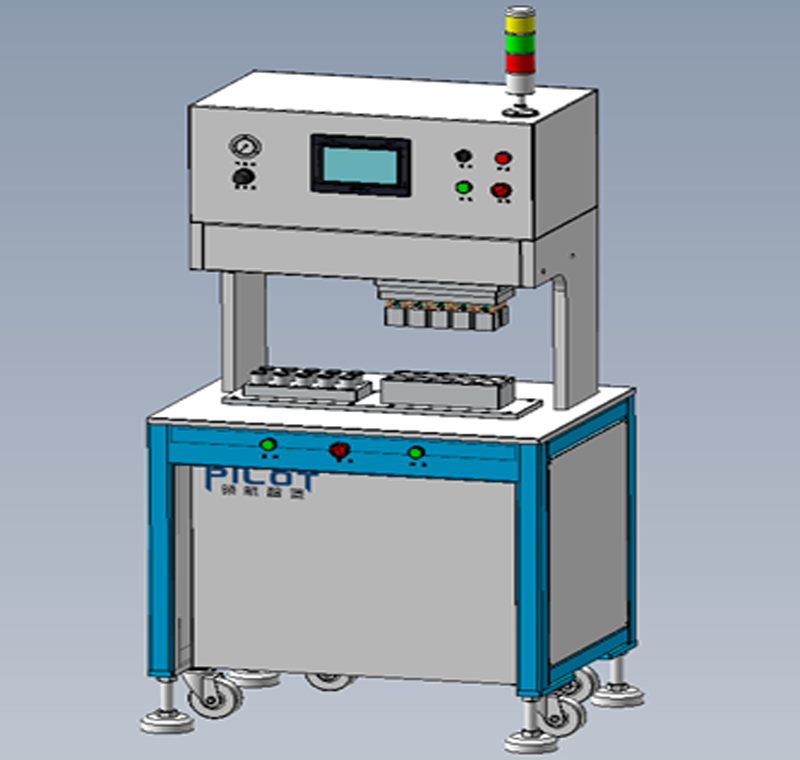

1. Glucose Test Strip Automatic Capping Machine Features:

This equipment automatically presses and seals the bottle caps after the glucose test strips are loaded into the bottles, enhancing the efficiency and quality of the capping process.

Caps 10 bottles simultaneously, with a comprehensive efficiency of up to 40 bottles/minute.

Bottle body and cap positioned by fixtures, which are easy to replace.

Precise positioning of bottle caps with vacuum adsorption to prevent displacement.

Elastic buffering during capping process with pressure monitoring to avoid crushing caps.

Enables one-time unloading via vacuum adsorption after capping, improving efficiency.

Simple button operation, no programming required, easy to use.

Photoelectric safety protection to prevent physical injury to the operator.

2. Workflow Diagram:

Manually load bottle bodies and caps onto the fixtures for positioning → Press the start switch → Platform moves into position, vacuum adsorbs the caps → Platform moves to the bottle bodies' position and presses the caps on → Capping completed, manual unloading (Automatic unloading function can be added as an option).

3. Equipment Parameters:

Working Pressure: ≤400 kg (Customizable)

Working Efficiency: Caps 10 bottles/simultaneously, comprehensive efficiency up to 40 bottles/min

Operation Method: Buttons and knobs (Pedal switch optional)

Working Air Pressure: 0.5 ~ 0.7 MPa

Machine Dimensions: Approx. 800mm * 600mm * 1800mm

Machine Weight: Approx. 150 kg

Power Supply: AC220V / 50 ~ 60 Hz